The grain size test initial data entry window covers basic information about the test and the sample tested. This window is displayed by clicking on the Sample Info. navigation tab, or by selecting Window > Sample Info.

Some items on the window may be automatically filled in by other data reduction modules. (For example, the sample's USCS classification is automatically calculated after the percent passing the #4 and #200 sieves and the soil's plastic and liquid limit are determined.) Leave these fields blank; after you've completed data entry for the lab tests, the missing information will be filled in for you.

- Because LabSuite supports a number of different report formats, the information requested on this screen varies according to which report format is selected; e.g., some formats may include a place for listing the sample's USCS classification, while others may omit this information.

You can select from the program's different report forms with the Report form toolbar at the top of the report preview window (Window > Report Preview).

While most of the information requested on the Sample Info. window is self-explanatory; a few require further definition:

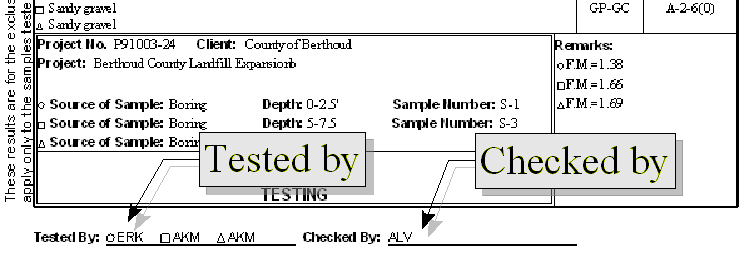

Checked by

If you fill in either of these fields, the information that you enter will be shown below the border of the test's chart report, as the following figure demonstrates:

Report With Tested By and Checked By

- When printing more than one test per page, LabSuite will use the "Checked by" name entered for the first test placed on the page.

LabSuite normally uses the material description that you entered into the Material Description field on the Data Manager window (that's the window with the numbered sample cards where you entered the sample's number, depth, etc.). However, if you're entering boring log data, the material description at the depth where you took your lab. test sample may only be something like:grades to slightly silty

with the full stratigraphy description entered at some depth above the lab. test sample. If this is the case, you can either override the default description or click on the link that reads Click here to select from a list of material descriptions: this drops down a box listing all of the material descriptions entered into the current source folder. Double-click on one of the descriptions to select it.

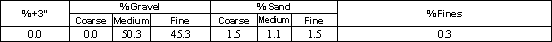

There are a number of systems used for subdividing material into gravel, sand, silt and clay, and each system has its own set of particle sizes determining those subdivisions. For example, the USCS system defines sand as material between #4 and #200 in size, while Burmister defines sand as being between #10 and #200. Additionally, Burmister does not distinguish between silt and clay sizes, and instead merely categorizes anything smaller than the #200 size as "fines", while Wentworth, for example, further divides into coarse/medium/fine/very fine silt, then clay.

You can select your preferred subdivision system for your test in the Particle gravel system box.

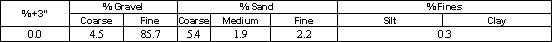

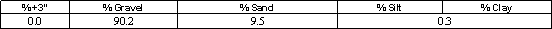

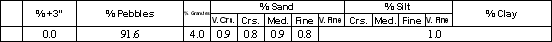

Your selection affects the percentages reported for gravel, sand, silt and clay, as well as the appearance of most of the program's chart reports. Following is a section of a GSGEOSYS report form printed for a test using different classification system selections:

USCS

USCS without coarse/medium/fine divisions

Wentworth

Burmister

There's three USCS selection options: "USCS with Silt/Clay Division at 2µ", "USCS with Silt/Clay Division at 5µ", and "USCS with Fines instead of Silt/Clay". The first two options stem from the fact that USCS and ASTM D2487 don't actually define silt and clay sizes, so the choice was open. (It appears that D653, the ASTM "Standard Terminology" document, will be modified -- per our suggestion -- to define clay as being larger than 2µ, so on new projects the first selection would be advised.) The final selection, "USCS with Fines instead of Silt/Clay", can be used on projects where the distinction between silt and clay is to be determined solely upon mechanical properties (i.e., Atterberg limits).

- We'll be posting more particle classification systems on our website as they're requested by LabSuite's users. Click on the More... button to view an updated list.

Specification envelopes provide upper and lower boundaries for some or all of the sieves in your test. For example, your client may require that a given delivered material test with 100% of its particles smaller than the 3/8" sieve, and with between 10% and 20% of its particles smaller than #200 sieve. The program maintains a database of specification envelopes taken from ASTM, AASHTO, Superpave and ISSA (International Slurry Surfacing Association) standards; you can also add your own envelopes to the database through the specification envelopes editor in the program's Setup dialog.

You can associate up to three specification envelopes with the test that you'll be entering by selecting the envelope names in the Specification boxes.

- To remove an existing envelope selection, select

(no specification envelope)instead.